From Micronic and Mydata to Mycronic.Following a successful merger, this high-tech Swedish company is pushing limits in the electronics industry, creating world-leading production solutions for the electronic assembly, display and electronic packaging industries. It’s a dynamic world where things happen fast and customers are always on the lookout for better solutions.

Our client. Mycronic is a Swedish high-tech company with 900 employees that has been active in the electronics industry for more than 30 years. It makes assembly equipment for the production of electronic products as well as pattern generators and mask writers used to create nearly all of the world’s flatscreen TVs, smartphones and tablets. Mycronic serves 2,500 customers in 50 countries and is listed on NASDAQ, Stockholm, Mid Cap.

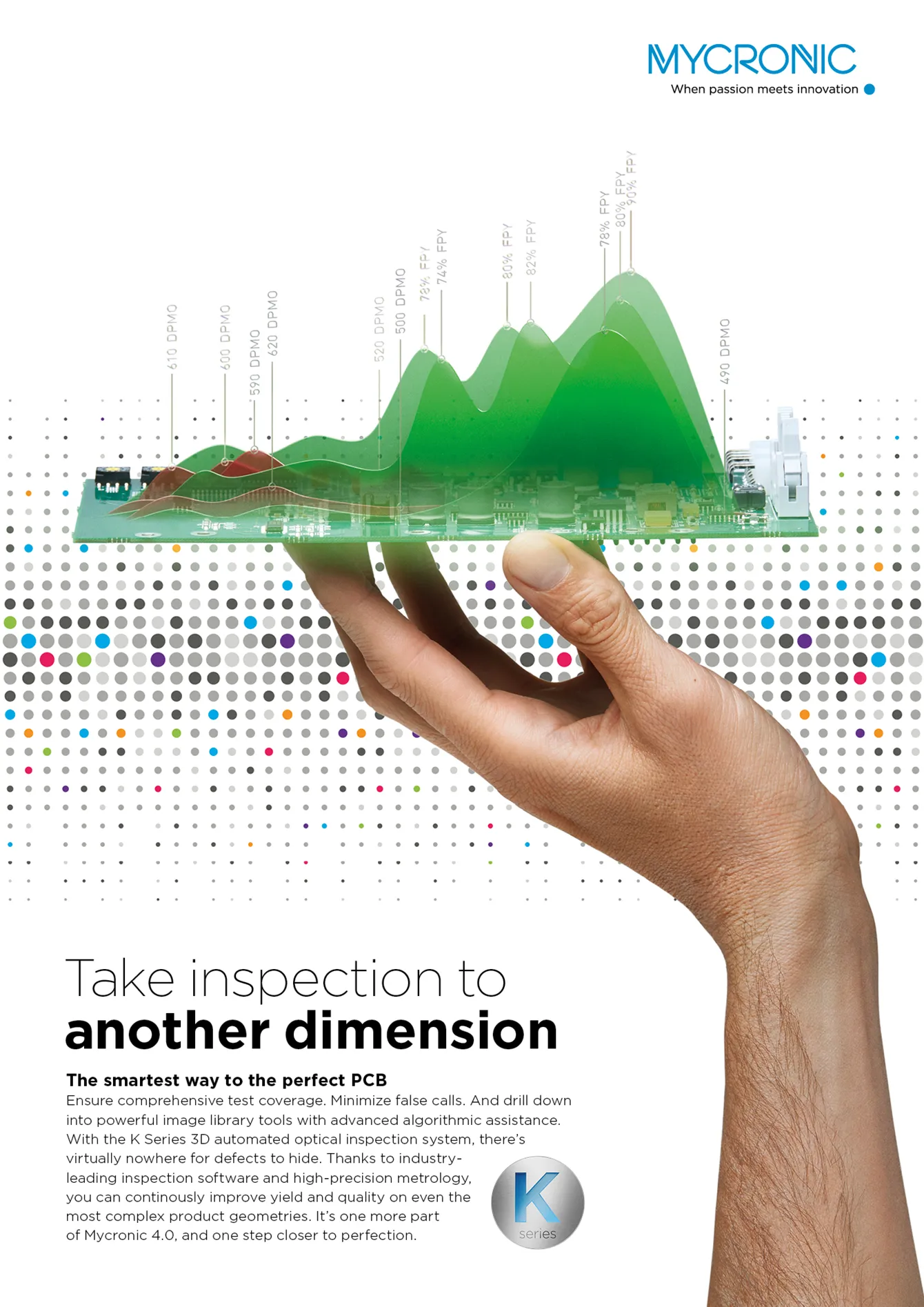

Our assignment. Mycronic was launching its MYPro series of pick-and-place and jet printing electronic assembly machines and wanted to communicate the value of the new range. In particular, it wanted to assure customers that any new investment would be future-proof and geared for Industry 4.0 connectivity, allowing greater precision, agility and productivity. The request was for an overall theme, messaging hierarchy and toolbox of online and offline tools, including all communications around the launch.

Our solution. The future of electronic production is anything but predictable. The trend is towards increasingly smaller components, a higher mix and smaller batches. Clearly, the term “just in time” manufacturing is more than a buzzword: it’s part of the new highly automated, just-in-time production that Mycronic has been enabling for years. Under the theme “The Future is Just in Time,” we produced a road show, press releases, web content, trade show design, editorial content and more. Sales have tripled over the past six years with 20% profitability.